A robot that takes care of weeding in the fields - all by itself

ETH Zurich provides the unique opportunity of working on a focus-project for engineering students in the third year of the bachelor’s degree. The focus project allows a team of 8 to 10 people to go through an entire product development process.

The main goal of each focus project is to let the students experience the whole process of developing a solution for a complex task from start to end. By doing so, each student deepens the know-how gained in the first two years of study and develops new skills such as management, marketing and communication. Through this process, students better understand what it means to work in a team and how to create and research new technologies. Teams are supported by sponsors and coaches from ETH throughout the duration of their projects.

What is Rowesys?

Rowesys stands for Robotic Weeding System. In only ten months we transformed an idea into a product.

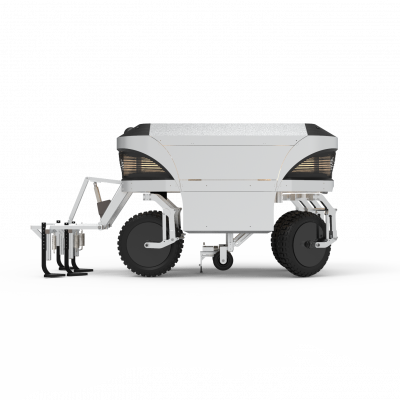

In short, Rowesys is a robot that navigates autonomously through sugarbeet fields, recognizes weeds, and destroys them without human interaction.

The hardware

What's underneath the casing?

The robot has an outer shell which protects all components within the casing. On the inside, it has two powerful batteries and an electrical box which contains most electrical components of the system. A structure made of aluminium profiles marks the skeleton of the robot.

weeding mechanism

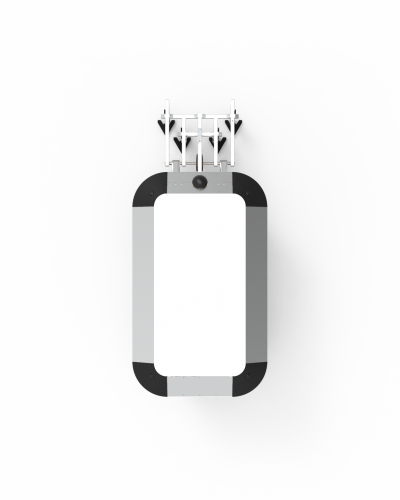

The passive tool

The passive weeding tool is used to remove weeds growing between rows of seeded crops. It consists of an arrangement of goose-foot spades which are individually mounted on a spring-suspended beam. This allows each goose-foot to move out of the ground individually in case of an obstacle in the soil. A linear motor from LINAK keeps the position of the beam frame fixed during operation and can lift the entire structure for maneuvering.

different Designs

how we design

Custom design

Since we were building a robot from scratch, we had the opportunity to design the necessary components by ourselves.

Generative Design

We used the newest technologies in order to build efficient and smart hardware.

hand crafted

After production we manually assembled all the components and sometimes adjusted details.

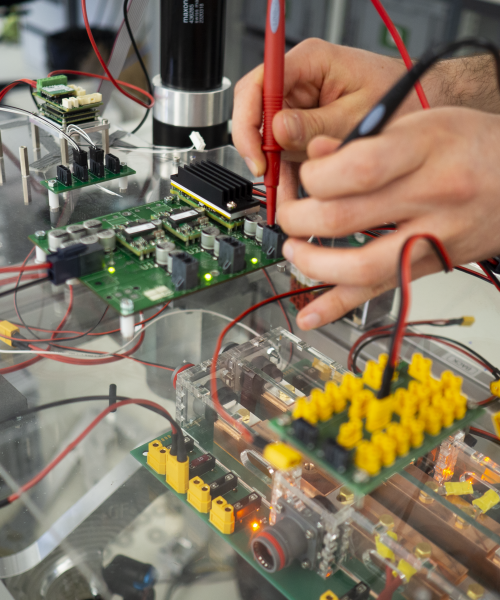

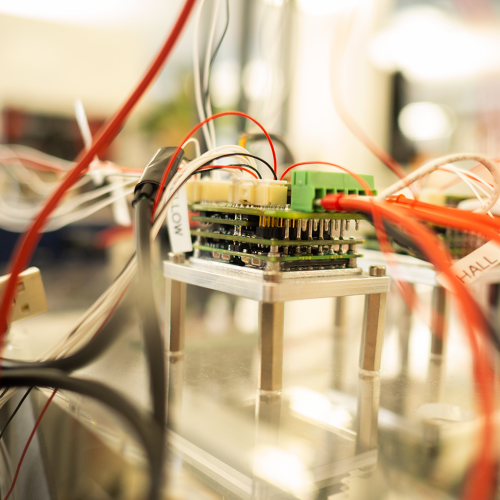

Controls

The powerful motor setup needs strong controllers. This is why we chose the “Elmo Motion Control” servo-drives which are very powerful and compact. Furthermore, the main computer needs to quickly send and receive information from the controllers. To enable this we used the EtherCAT field-bus system.

our expertise

Vision

The robot navigates using two different sensors: A depth camera as well as a tracking camera. The depth camera is used to extract the position of the robot relative to the row.

The tracking camera, in combination with its precise IMU, is used to estimate the position of the system and use this information to optimize the row-detection over several frames.

Steering mechanism

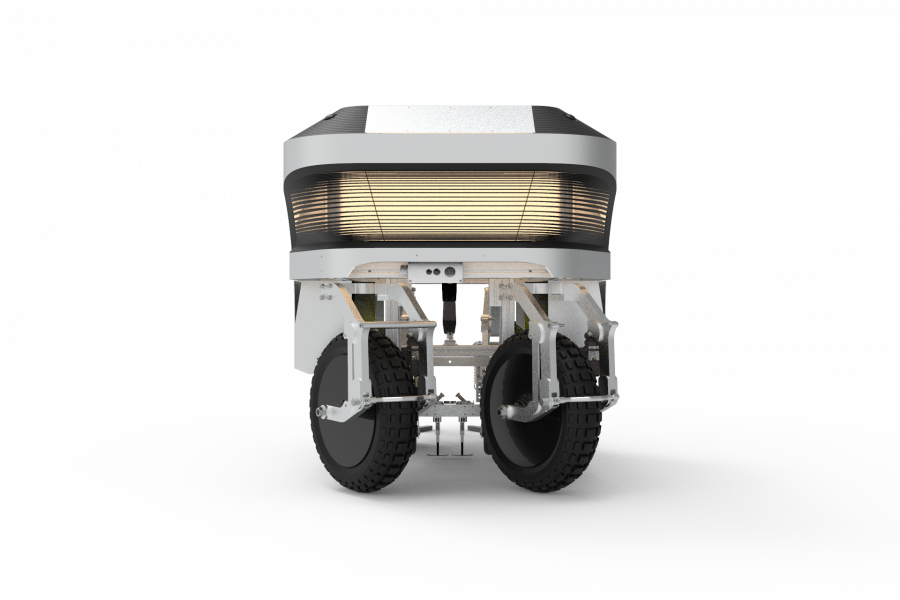

The steering mechanism of choice is swerve drive. The concept is implemented by allowing each wheel to orient itself independently. This allows for turning on the spot as well as crab steering which gives the system the means to cope with uneven terrain. To provide the necessary steering torque, maxon motors in combination with maxon planetary gearboxes are implemented. Additionally – to measure the wheel’s orientation – absolute encoders from the company Baumer are integrated within the steering mechanism.

The Casing

The casing presents our work to the outside and is the first impression we make. Therefore, we were looking to present the futuristic autonomous aspect of our project, as well as the easy to use, agricultural aspect.

So we tried to bring this into a form that allows to excite without overwhelming the viewer.

The bent aluminium is light and gives the robot a shiny look.

The black part is 3D printed carbon enhanced plastic that gives the robot its distinctive front and back while being extra stable and allowing complex forms.

Behind the casing a LED feeds the current status of the robot back to the user.

Hatches on the side allow for easy access to the electronics and on-board computer.

“The casing allows us to promote our idea to a broader group of people “

- LED feedback

- Lightweight

- Easy accessible